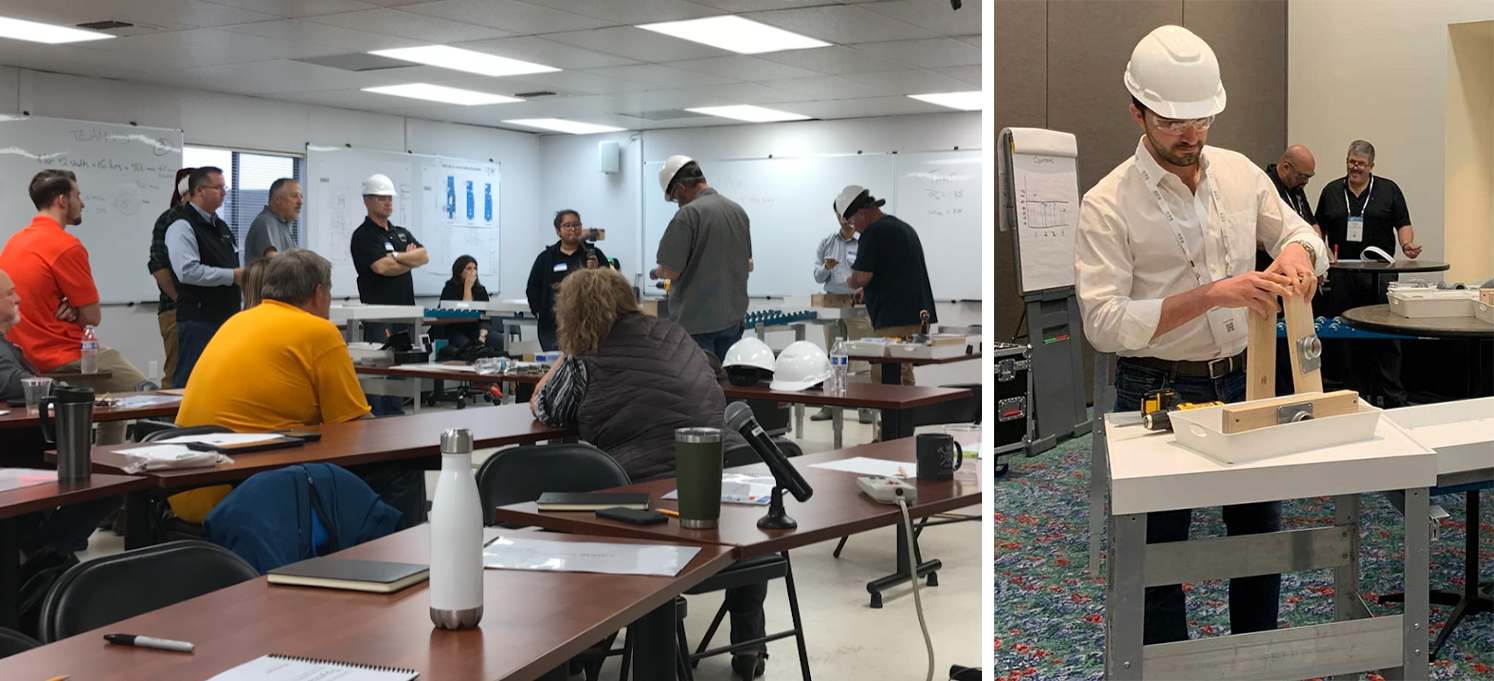

Setting a Tone of Collaboration

Teaming and Lean learning for an IPD team working a hospital bed tower addition

Background

Following study mission trips to Toyota City in Japan, Boulder Associates developed a mobile lean learning lab used for training project teams in lean skills while building collaboration and integrated behaviors called the TPS Dojo.

Obstacle

The project team was looking for a way to kick start collaboration among the trades as they mobilized for the start of work in the field. They also wanted to get the team on the same page regarding lean thinking.

Approach

The teaching method relies on an instructional version of the Deming Cycle: each segment follows a PDCA format of learning new concepts, smaller teams planning and applying on the assembly line, and shared reflection applied on multiple cycles of classroom learning and hands-on assembly.

The day began with a brief overview of the Toyota Production System and basic lean concepts of pull and takt, as well as introducing the mobile assembly line. The team divided into teams, planned how to assemble the widget, assigned people to work stations, and completed the first cycle of assembly. The teams reported out, compared observations, and reflected on their experience.

The group then returned to the classroom for more lean concepts, including how to develop standard work, before beginning a second cycle of assembly. This time, the teams received standard work manuals that showed a clear method for assembling the widget. The teams then planned, executed, observed, and reflected on their efforts.

Final classroom instruction focused on application of examples to the design and construction process. In a third assembly cycle, teams were free to make any improvements they wished to the assembly process. Teams engaged in friendly competition and built enduring bonds that carried on to the project.

Result

The team found the workshop to be extremely valuable. Teammates reported on the effectiveness of the lean level set and enjoyed the practical, hands-on experience of building the widget on the assembly line, noting that lessons of the workshop were referenced frequently in the following months.

Lessons Learned

Great value to the project comes from the team that goes through the workshop experience together.

Everyone who participated benefited from the exercise. Despite concern about the relevance of a manufacturing approach, participants from owner, design, and build backgrounds found value in collaborating together.

Recommendation: Bring together team members from all groups of stakeholders.

Preparing for a build cycle on the assembly line was super valuable. The highlight for most participants was the collaborative planning the small groups did when they were allowed to make their own improvements from the standard assembly work, finding this to be an exciting opportunity to work with teammates in a creative manner.

Recommendation: Focus on supporting the build teams as they are allowed to make improvements beyond the standard work.